Dust, Dreams, and Desert Riches: The Enduring Legacy of California’s Borax Mines

The Mojave Desert, a landscape of stark beauty and unforgiving extremes, holds more than just Joshua trees and shimmering heat haze. Beneath its sun-baked surface lies a mineral treasure that shaped industries, forged legends, and continues to fuel a global demand: borax. For over a century, California has been the undisputed heartland of borax mining, a story woven with tales of incredible human endurance, technological innovation, and an enduring connection to the very fabric of American enterprise.

From the iconic 20 Mule Team to the colossal open-pit operations of today, the journey of California’s borax has been one of relentless pursuit, transforming a seemingly obscure mineral into a household staple and an indispensable component in countless modern technologies. It’s a narrative that speaks not just of geology and industry, but of the pioneering spirit that tamed one of the world’s harshest environments.

The Genesis of a Giant: From Desert Discovery to Legend

The story of California borax truly begins in the latter half of the 19th century, a time when prospectors scoured the West not just for gold and silver, but for any mineral that could yield a fortune. Borax, a naturally occurring salt of boric acid, was initially discovered in significant quantities in Nevada, notably at Teel’s Marsh in 1862. But it was California’s vast, ancient lakebeds, formed by evaporating waters over millennia, that held the greatest promise.

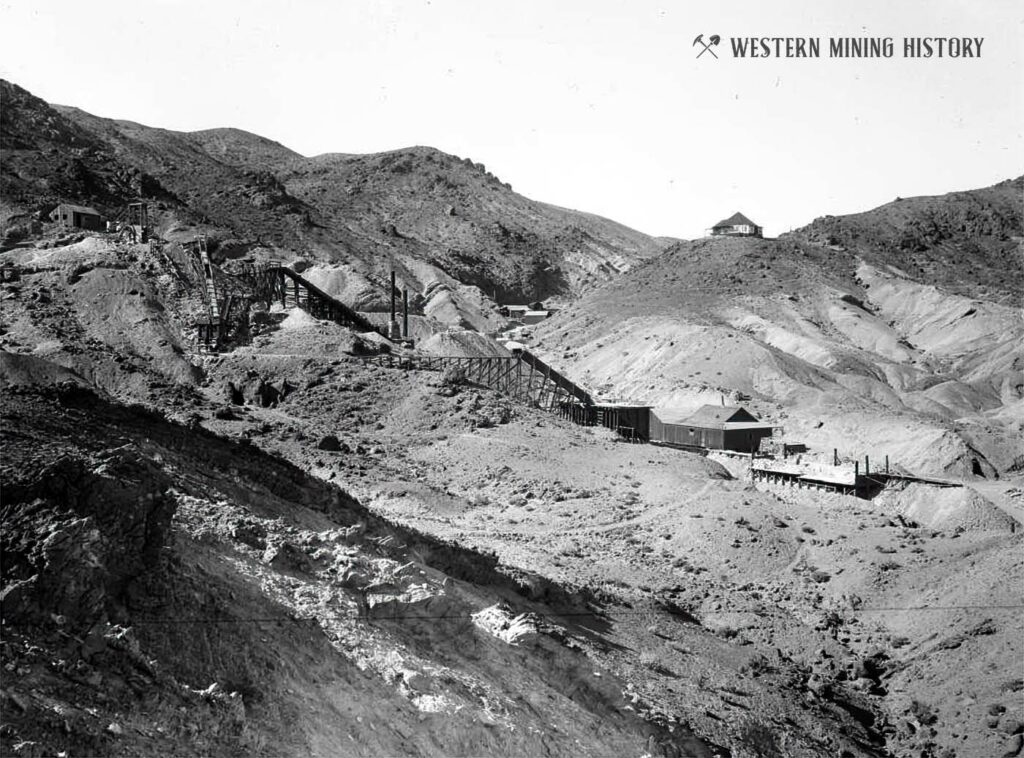

The seminal moment for California borax arrived in the early 1880s with the discovery of rich deposits in Death Valley. William Tell Coleman, an astute businessman, quickly moved to capitalize on these finds. The challenge, however, was immense. Death Valley lived up to its name, presenting a brutal landscape of extreme heat, lack of water, and isolation. Transporting the crude borate ore, known as "cottonball" for its appearance, over 165 miles of rugged, unpaved terrain to the nearest railhead at Mojave was an engineering and logistical nightmare.

This challenge gave birth to one of the most enduring symbols of American industry: the 20 Mule Team. From 1883 to 1889, these colossal teams, consisting of 18 mules and two horses pulling massive wagons laden with 10 tons of borax, made the arduous journey. "It was an epic feat of strength and coordination," explains Dr. Evelyn Reed, a historian specializing in industrial archaeology of the American West. "The drivers, or ‘borax skinners,’ were legends in their own right, navigating those immense rigs through some of the most unforgiving country imaginable. The 20 Mule Team wasn’t just a transport method; it became a powerful marketing icon that forever linked borax with grit and perseverance."

The imagery of the 20 Mule Team, later immortalized in popular culture and advertising, ingrained borax into the American consciousness, turning a once-specialized chemical into a household name for cleaning and laundry.

The Shift to Kramer: A New Era of Abundance

While Death Valley cemented borax’s place in history, the true industrial heart of California borax mining would eventually shift. The Death Valley operations, though legendary, were labor-intensive and geographically challenging. The discovery of a vast, high-grade borax deposit near Kramer (now Boron), California, in the late 1920s, marked a pivotal moment.

This new deposit, a massive, lens-shaped body of colemanite and kernite, was far more accessible and of significantly higher purity than the Death Valley finds. Francis Marion "Borax" Smith, another titan of the industry, who had consolidated various borax interests into the Pacific Coast Borax Company, played a crucial role in developing these new reserves. The Kramer deposit allowed for a transition from smaller-scale, more scattered operations to a consolidated, highly efficient mining process.

Today, the Kramer Mine, operated by Rio Tinto Minerals, is the largest borax mine in the world, supplying a significant portion of the globe’s demand. It’s a stark contrast to the pick-and-shovel days of the 19th century. The mine is an immense open-pit operation, a man-made canyon stretching over two miles long, a mile wide, and nearly 1,000 feet deep.

"Looking down into the pit is like gazing into another world," says Maria Sanchez, a resident of Boron whose family has worked at the mine for three generations. "The trucks are like houses on wheels, and the scale of everything just makes you feel tiny. But it’s also a testament to human ingenuity – taking something from deep underground and turning it into thousands of products."

The scale of operations is staggering. Gigantic haul trucks, capable of carrying hundreds of tons of ore, traverse meticulously engineered ramps, moving millions of tons of material each year. The ore is then crushed and transported to a sophisticated processing plant where it undergoes a series of steps – including dissolving, filtering, crystallization, and drying – to produce various refined borate products. This modern process ensures a consistent, high-purity output essential for contemporary industrial applications.

The Ubiquitous Mineral: Borax in the Modern World

Beyond its historical fame as a cleaning agent, borax and its derivatives are remarkably versatile and fundamental to countless modern industries. Its unique chemical properties make it indispensable in ways most people never realize.

"Borax is one of those hidden workhorses of the global economy," states Dr. Kevin Chang, a materials scientist at UC Berkeley. "Its ability to act as a flux, a buffer, a flame retardant, and a micronutrient means it touches almost every aspect of our lives, from the glass in our smartphones to the insulation in our homes."

Here are just a few of its critical applications:

- Glass and Ceramics: Borax lowers the melting point of glass, improves its strength, durability, and resistance to thermal shock. It’s crucial for everything from Pyrex cookware to fiberglass insulation and LCD screens. In ceramics, it acts as a flux, helping glazes adhere and flow smoothly.

- Detergents and Cleaning Products: Its alkalinity and water-softening properties make it an effective cleaning booster, stain remover, and deodorizer.

- Agriculture: Boron is an essential micronutrient for plant growth. Borax is used as a fertilizer additive to ensure healthy crop yields, especially in fruits, vegetables, and nuts.

- Flame Retardants: Boron compounds are used in various materials to enhance fire resistance, particularly in wood products, textiles, and plastics.

- Metallurgy: As a flux in metal smelting and welding, borax helps remove impurities and protect molten metal from oxidation.

- Nuclear Industry: Boron’s ability to absorb neutrons makes it valuable in nuclear reactors for control rods and as a shielding material.

- Adhesives: Borax improves the tack and strength of starch-based adhesives, used in cardboard, paper, and plywood.

- Personal Care Products: Small amounts of borax can be found in some cosmetics and pharmaceuticals.

This extensive list underscores the quiet but pervasive influence of California’s desert mineral on global manufacturing and consumer goods.

Environmental Stewardship and Community Impact

Mining, by its very nature, is an extractive industry with environmental considerations. In the arid Mojave, water usage and dust control are paramount concerns. Rio Tinto, like other major mining operations, faces scrutiny and holds a responsibility to mitigate its impact.

"Operating in such a sensitive desert ecosystem requires constant vigilance and innovation," states a Rio Tinto spokesperson, emphasizing the company’s commitment to sustainable practices. "We employ extensive dust suppression techniques, including water sprays and revegetation efforts. Water conservation is critical, and we’ve invested heavily in recycling technologies to minimize our freshwater footprint." The company also engages in progressive reclamation, reshaping and revegetating areas of the mine that are no longer active, aiming to restore them to a state that supports local flora and fauna.

Beyond environmental considerations, the Boron mine has a profound impact on its local community. The town of Boron, California, exists because of the mine. It’s a classic company town, though now more diversified, where generations have found stable employment and a sense of community. The mine provides hundreds of direct jobs, along with numerous indirect jobs in supporting services, making it the economic engine of the region.

"This mine is the lifeblood of our town," says Robert Jensen, a long-time Boron resident and former mine employee. "It’s not just a job; it’s a way of life. The mine provides opportunities, supports local businesses, and has been a stable presence for decades. We’ve seen booms and busts, but the borax keeps coming out of the ground."

The Future of Desert Riches

As the world continues to evolve, so too does the demand for minerals like borax. New applications are constantly being explored, from advanced battery technologies to specialized materials for aerospace. The challenge for California’s borax industry lies in balancing this growing demand with responsible mining practices, ensuring the longevity of the resource and the health of the environment.

The story of California’s borax mining is a testament to the enduring power of natural resources and human ingenuity. From the back-breaking labor of the 20 Mule Teams traversing Death Valley to the high-tech, data-driven operations of today’s open-pit mine, it’s a narrative of adaptation, perseverance, and global significance. The dust of the Mojave may obscure its secrets, but beneath the surface, California’s borax continues to shape our world, a quiet, indispensable force forged in the heart of the desert.