Titans of the Earth: How Western Mining Manufacturing Forges the Future of Extraction

DENVER, CO – In the rugged heartland where mountains meet innovation, a silent revolution is underway, driven by the colossal machines that carve out the very resources powering our modern world. At the epicenter of this transformation stands Western Mining Manufacturing (WMM), a company that has, for over a century, been the bedrock of global extraction. From the dusty gold fields of the American West to the technologically advanced mega-mines of the 21st century, WMM has consistently delivered the brawn and the brains, blending heritage with cutting-edge technology to redefine what’s possible beneath our feet.

With its sprawling headquarters nestled against the backdrop of the Rockies in Denver, Colorado, WMM isn’t just building equipment; it’s engineering the future of an industry often perceived through a narrow, historical lens. Today, mining is less about picks and shovels and more about AI-driven automation, sustainable practices, and unprecedented precision. And WMM is leading the charge.

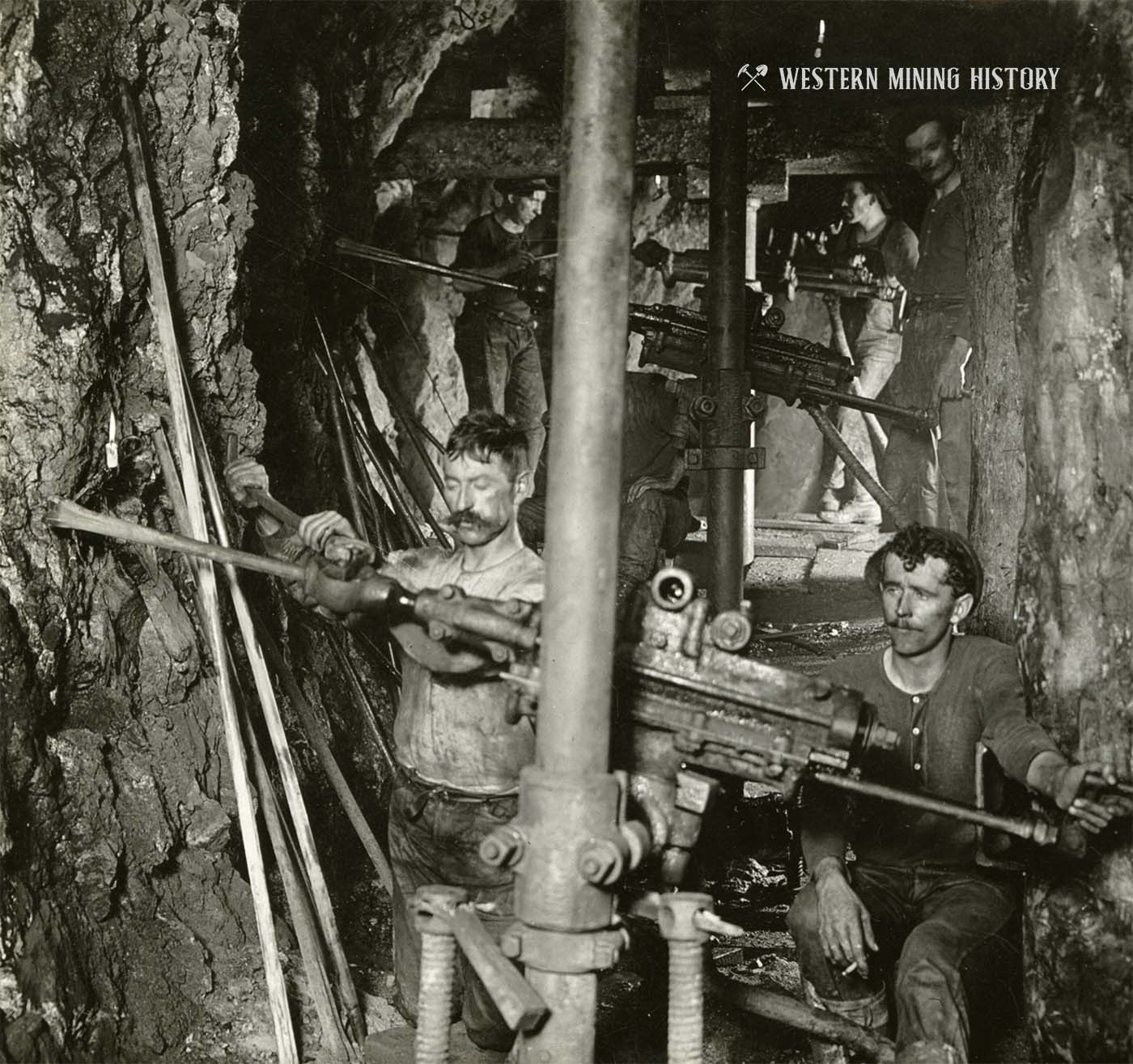

A Legacy Forged in Steel and Grit

The story of Western Mining Manufacturing begins, as many great American industrial tales do, with ingenuity born of necessity. Founded in 1905 by Elias Thorne, a pragmatic engineer with a keen eye for efficiency, WMM started as a small workshop supplying robust, reliable tools to the burgeoning gold and silver mines dotting the Western landscape. Thorne’s early designs for ore crushers and conveyor systems quickly earned a reputation for durability, outlasting competitors in the harsh conditions of the Rocky Mountains.

"Our roots are deeply embedded in the spirit of the American West," states Marcus Thorne, Elias’s great-grandson and WMM’s current CEO, during a rare interview at the company’s Denver campus. "My great-grandfather understood that reliable machinery wasn’t just a commodity; it was a lifeline for these operations. That ethos of unwavering dependability, forged in the crucible of hard labor, still defines every piece of equipment we build today."

Over the decades, WMM grew alongside the industry it served. The post-war boom saw the company pivot to larger-scale earthmoving equipment. The 1970s brought the advent of massive haul trucks, and WMM was at the forefront, designing vehicles that could carry hundreds of tons with unprecedented efficiency. This continuous evolution, adapting to the changing demands of global resource extraction, cemented WMM’s status as a formidable player.

The Heart of Innovation: Denver’s Digital Foundry

Today, WMM’s Denver campus is a testament to this evolution. Spanning over 500 acres, it houses not only state-of-the-art manufacturing facilities but also advanced R&D labs, robotics testing grounds, and one of the industry’s most comprehensive training centers. Here, the clatter of heavy machinery mingles with the hum of servers processing petabytes of data, a stark reminder of the industry’s hybrid future.

"It’s no longer just about building the biggest truck," explains Dr. Anya Sharma, Head of Research & Development at WMM, her voice animated as she gestures towards a holographic display of a mine layout. "It’s about making that truck smart, connected, and ultimately, autonomous. We’re integrating artificial intelligence, advanced sensor arrays, and predictive analytics into every piece of equipment we produce."

WMM’s flagship innovations include their "Guardian" series of autonomous haul systems (AHS), which allows massive vehicles to navigate complex mine paths without human operators, significantly enhancing safety and operational efficiency. Furthermore, their "GeoInsight" platform leverages machine learning to analyze geological data, optimizing excavation plans and reducing waste. These technologies aren’t just theoretical; they are deployed in some of the world’s largest copper, iron ore, and diamond mines.

A recent case study from a major Australian iron ore mine demonstrated a 15% increase in operational throughput and a 20% reduction in fuel consumption after implementing WMM’s Guardian AHS and GeoInsight systems. "The data speaks for itself," notes Eleanor Vance, an independent mining consultant who frequently works with WMM’s clients. "WMM isn’t just selling hardware; they’re selling an integrated solution that directly impacts the bottom line and improves safety."

Sustainability: Mining a Greener Future

In an era of increasing environmental consciousness, the mining industry faces intense scrutiny. WMM understands this challenge deeply and has made sustainability a core pillar of its strategy, moving far beyond mere compliance.

"We recognize our responsibility to the planet," says Sarah Jenkins, WMM’s Chief Sustainability Officer. "Our ‘EcoMine Initiative’ is not just a marketing slogan; it’s a fundamental shift in how we design, manufacture, and operate. This includes developing electric and hydrogen-powered mining vehicles, designing equipment for minimal environmental footprint, and pioneering closed-loop water systems for our own manufacturing processes."

WMM has invested heavily in technologies that reduce energy consumption in their equipment, such as regenerative braking systems in their haul trucks and energy-efficient motors in their crushers. They are also exploring advanced mineral processing technologies that minimize water usage and reduce tailings waste. This commitment extends to their supply chain, with rigorous standards for ethical sourcing of materials.

"It’s about creating a circular economy within mining," Jenkins elaborates. "We’re not just taking; we’re also giving back by ensuring our operations and our products contribute to a more sustainable future. Our aim is to make ‘responsible mining’ the industry standard, not an exception."

Global Reach, Local Impact

While WMM’s influence spans continents—with equipment operating in over 60 countries across diverse terrains, from the frigid Arctic to the humid tropics—its impact remains deeply felt in its home state of Colorado. The company employs over 3,000 direct personnel in the state, from highly skilled engineers and software developers to expert welders and machinists. Its economic ripple effect extends further, supporting countless local businesses and contributing significantly to the regional economy.

"We pride ourselves on fostering a culture of innovation, safety, and continuous learning," states Maria Rodriguez, WMM’s VP of Human Resources. "Our employees are our greatest asset. We invest heavily in training programs, apprenticeships, and collaborative workspaces to ensure we attract and retain the best talent. Many of our employees have been with us for decades, a testament to the strong community we’ve built here."

Mark Ramirez, a veteran machinist who has been with WMM for 35 years, reflects on his journey. "When I started, it was all manual blueprints and heavy lifting. Now, I work alongside robots, programming them to precision-cut steel. The company has always pushed us to learn, to adapt. It feels like we’re not just building machines; we’re building the future, one piece at a time."

Navigating the Future: Challenges and Opportunities

The path ahead for WMM, and the mining industry as a whole, is not without its challenges. Geopolitical shifts, volatile commodity prices, increasingly stringent environmental regulations, and the persistent need for a skilled workforce all present hurdles. Supply chain resilience, highlighted by recent global disruptions, is also a critical focus.

However, WMM views these challenges as opportunities for further innovation. The company is actively exploring new frontiers, including deep-sea mineral extraction technologies and even conceptual designs for lunar and asteroid mining equipment, anticipating the resource needs of future generations.

"The demand for raw materials isn’t going away; it’s only going to intensify as the world electrifies and digitalizes," CEO Marcus Thorne asserts. "Our role is to ensure that these essential resources can be extracted safely, efficiently, and with minimal environmental impact. We are constantly pushing the boundaries of engineering and technology to meet that demand responsibly."

As the sun sets over the Rockies, casting long shadows over WMM’s vast campus, it’s clear that Western Mining Manufacturing is more than just a company building heavy machinery. It is a vital cog in the global economy, a pioneer of technological advancement, and a powerful force shaping the future of resource management. By blending its storied past with an unwavering commitment to innovation and sustainability, WMM continues to prove that even in the most traditional industries, the future is always being forged, one colossal machine at a time.